Rössing Uranium is committed to protecting the environment in which we operate. With cognisance on how our mining operations impact natural resources and the environment, we drive a wide range of preventative monitoring activities.

We have a particular focus on water management and monitoring, especially considering the extreme rainfall conditions associated with the Erongo region’s water-scarce and hyper-arid climate. We have a strong history of engagement and co-operation with our regulators and other stakeholders to ensure that the environment remains protected.

We manage impacts on the environment with guidance from, among others, Namibian legislation, the ISO 14001:2015 Environmental Management System, Rössing Uranium’s performance standards, and international best practices.

Through transparent reporting, we provide our stakeholders with the assurance that our environmental impacts are monitored, and the necessary mitigation measures are in place to keep our environmental impacts minimal. Our environmental management performance, measured against set objectives and plans, is discussed on the pages that follow.

Water management

Water management at Rössing Uranium is guided by a formal water strategy, a water management plan, and a Rössing-specific environmental standard on water usage and quality management.

These management tools cover all activities related to water abstraction, transport, storage and usage (potable and process), as well as impounded water and groundwater. The intention of the standard isto ensure efficient, safe, and sustainable use and protection of water resources and ecosystems.

In addition, Rössing Uranium adheres to all aspects pertaining to water in the Constitution of the Republic of Namibia. To that effect, we operate with a Wastewater and Effluent Disposal ExemptionPermit 674, as well as a Water Abstraction Permit 10200.

Knowing that our water requirements are substantial, our focus is on the sustainable and accountableuse of this scarce and valuable resource, with minimal adverse effect to the environment.

We carry out various continuous monitoring activities, which include:

- Taking frequent flow-meter readings at various points in the processing plant to provide a continuous overview of our water balance data.

- Taking frequent water level measurements on our tailings storage facility (“TSF”) and numerous monitoring locations across the mine site, extending to the Khan and Swakop Rivers.

- Conducting water quality sampling at various locations (starting at the source, the TSF), which we use to understand changes in water chemistry due to chemical reactions in the heterogeneous environment.

All spillages in the processing plant are captured and channelled to a large recycle sump for reuse. Effluents from the workshops are treated to remove oils and sewage is processed in the onsite sewageplant. These semi-purified effluents are used in the open pit for dust suppression.

At the deposition pool (active paddy) of the TSF, water is recycled and reused on a continuous basis in the processing plant, minimising surface evaporation and infiltration into the tailings pile. Water that infiltrates the TSF is recovered by pumping boreholes and open trenches installed on the facility itselfto reduce the volume of underground water within the tailings pile.

Seepage control systems are also employed outside the TSF. They include a surface seepage collection dam to capture water from the engineered tailings toe drains, cut-off trenches in sand-filled river channels, dewatering boreholes situated on geological faults and fracture systems on the downstream, western side of the facility. All systems are designed to lower the water table to the extent that flowtowards the Khan River is interrupted. The recovered water is reused in the processing plant.

Freshwater use

Our water demand is met by the local bulk water supplier, NamWater, via a pipeline from the base reservoirs in Swakopmund and is sourced from the Orano desalination plant near Wlotzkasbaken. Freshwater supply continues to be a challenge for our operation, as our demands are not always met due to engineered or otherwise natural challenges experienced by the suppliers.

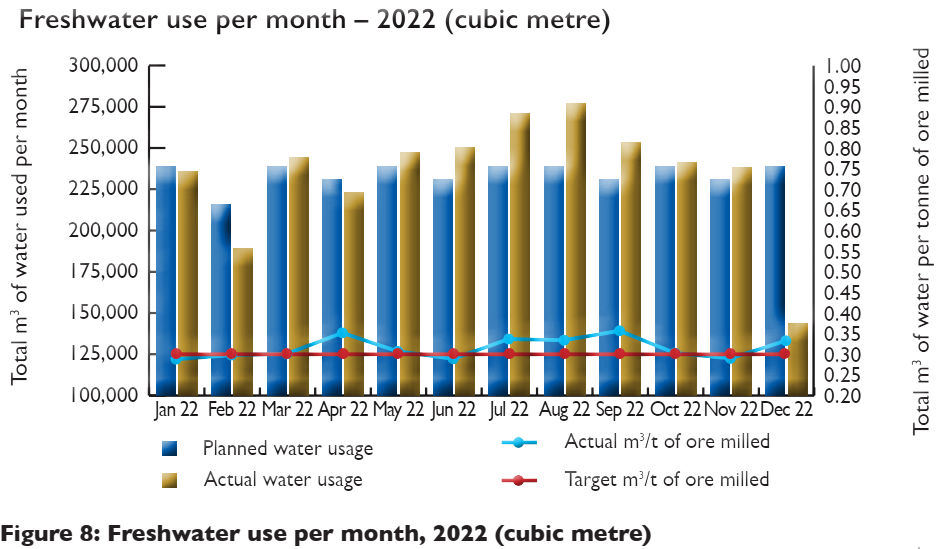

For 2022, we kept our freshwater usage target which was set in 2021 unchanged at 2,814,150m3 of freshwater for all operations. Our actual freshwater consumption for 2022 was 2,768,768m3 which, although higher than what was used in 2021 (2,723,508m3), remains below the planned target of 2.0 per cent.

Monthly freshwater usage, as depicted in Figure 10, was above plan for most of 2022. This is attributed to low return dam solution recovery from the active paddocks, for which the deficit had to be supplemented with fresh water. Similarly on the same figure, water usage per tonne of ore milled records correlate to freshwater usage, with ratios above the set target for some months.

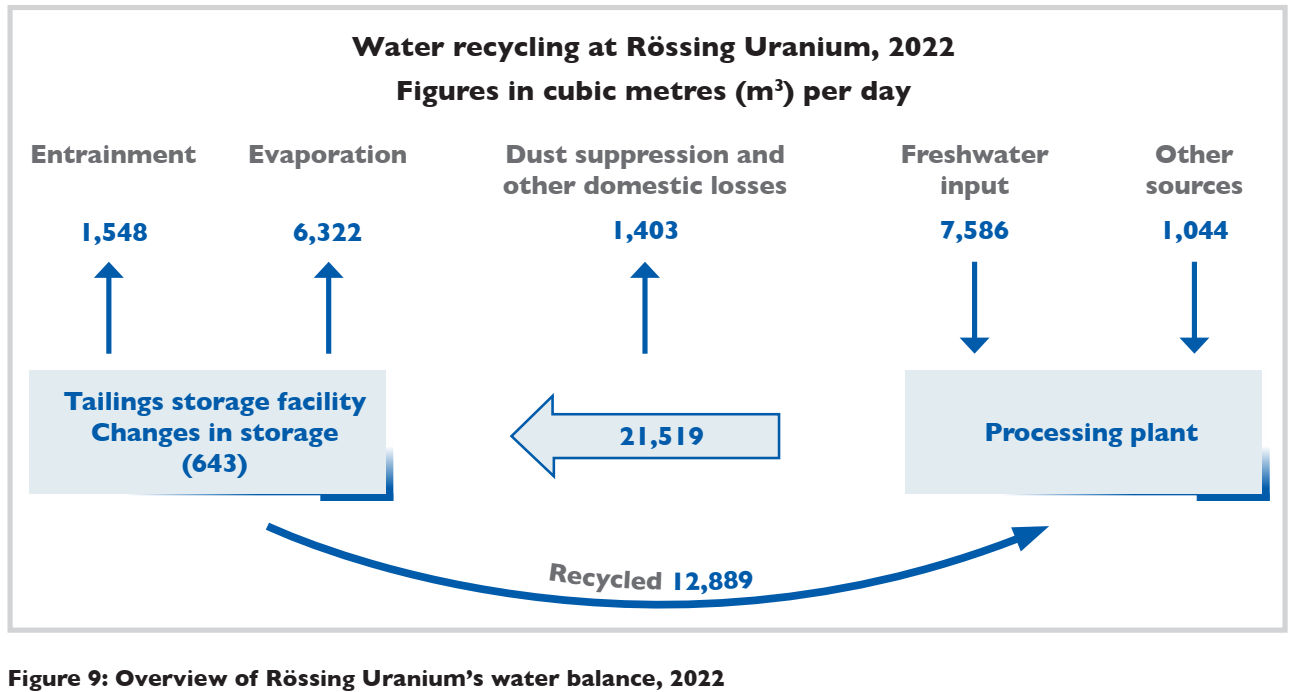

Credits from our continuous improvements and sustained infrastructure maintenance remain visible in our total recycled volumes, with 59.9 per cent of the total water usage (see Figure 9) accredited to recycling.

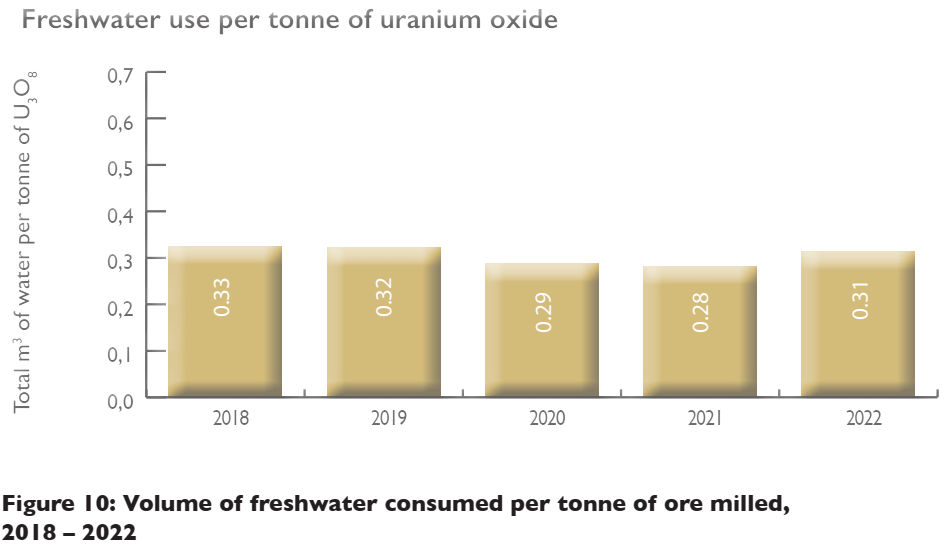

Our freshwater consumption performance from 2018 until 2022 is depicted in Figure 10.

Khan River water use

Saline groundwater from the Khan River aquifer, in conjunction with biodegradable dust suppressant polymers, is used for the purpose of haul-road dust suppression in the open pit. A total of 4,780m3 of water was abstracted from the aquifer during 2022, which is 0.55 per cent of the permitted 870,000m3 per year (5.4% in 2021). Although our abstraction from the river remains minimal, we continue our monitoring obligations. In compliance with the abstraction permit conditions, annual reports derived from the water-level and vegetation-monitoring programmes are sent to the Ministry of Agriculture, Water and Land Reform

Air quality management

Rössing Uranium is committed to protecting the environment from the harmful effects of air pollution caused by its mining activities. Dust is generated during blasting, the loading and dumping of ore and waste, as well as during the crushing and conveying of ore. Winds at speeds above 30km/h potentially mobilise fine particles from rock dumps and the TSF and disperse them into the environment. Dust particles can be so small that they become airborne, easily causing environmental effects such as reduced visibility, increased acidity in water bodies, and lessening of the soil with the resultant damage to plants.

In addition, noise and ground vibrations are created during mining operations including blasting, while the machinery deployed in the open pit and the processing plant generates noise continuously.

Therefore, dust emissions, noise and ground vibrations created during mining activities require an understanding of the impact they have on the people and the environment. Hence, an air-quality monitoring programme (“AQMP”) is in place to measure and monitor air pollutants in the mining and surrounding areas. This guides us in implementing programmes to help reduce these impacts.

Environmental dust

Rössing Uranium is located in an arid environment and the climatic conditions make dust an inevitable reality. Dust emissions are of concern to the residents of Arandis and Swakopmund, especially when high velocity winds occur during the winter months.

To quantify the dust fallout generated by our mining activities and allow mitigation when necessary, the AQMP is in place. Measures are taken to ensure that exposure levels do not exceed the adopted occupational limits, and that the controls efficiently detect differentiations resulting from process changes.

Two types of dust are measured: firstly, a very fine dust (invisible to the naked eye) that is comprised of particulate matter less than 10 micron (known as PM10); and secondly, fallout dust, which is visible to the naked eye and is comprised of lager particles, but also includes PM10.

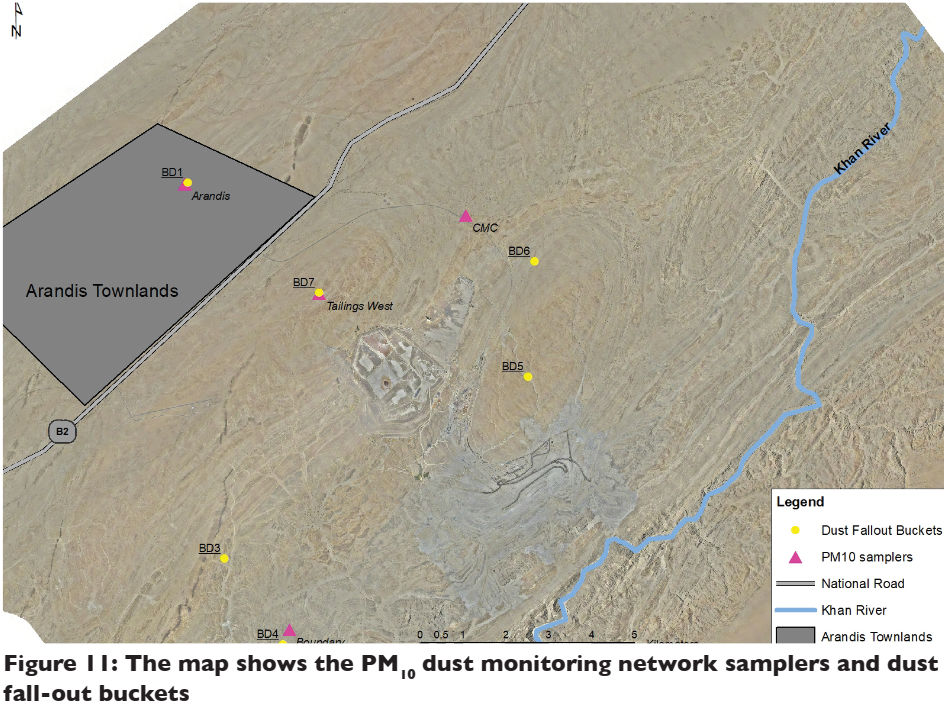

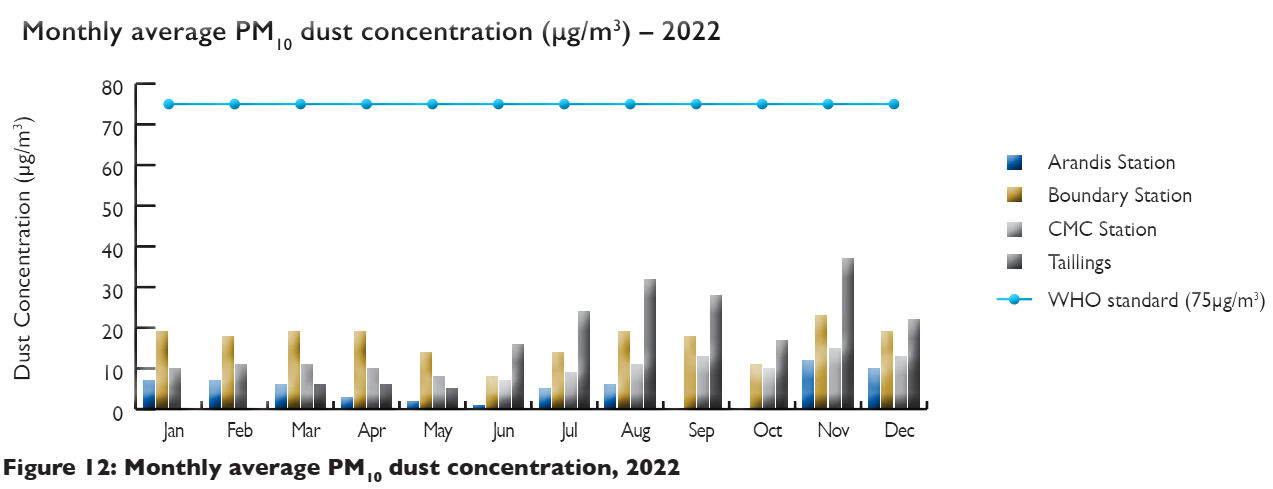

The measure of PM10 is the concentration of particles less than, or equal to, ten micrometres in diameter in one cubic metre of air. We continuously monitor PM10 dust levels at four monitor stations: three onsite and one in the nearby town of Arandis (see Figure 11, denoted by pink triangles)

The levels measured in 2022 showed that the PM10 dust concentrations at the available stations were below the adopted World Health Organization standard of 75μg/m3 (see Figure 12).

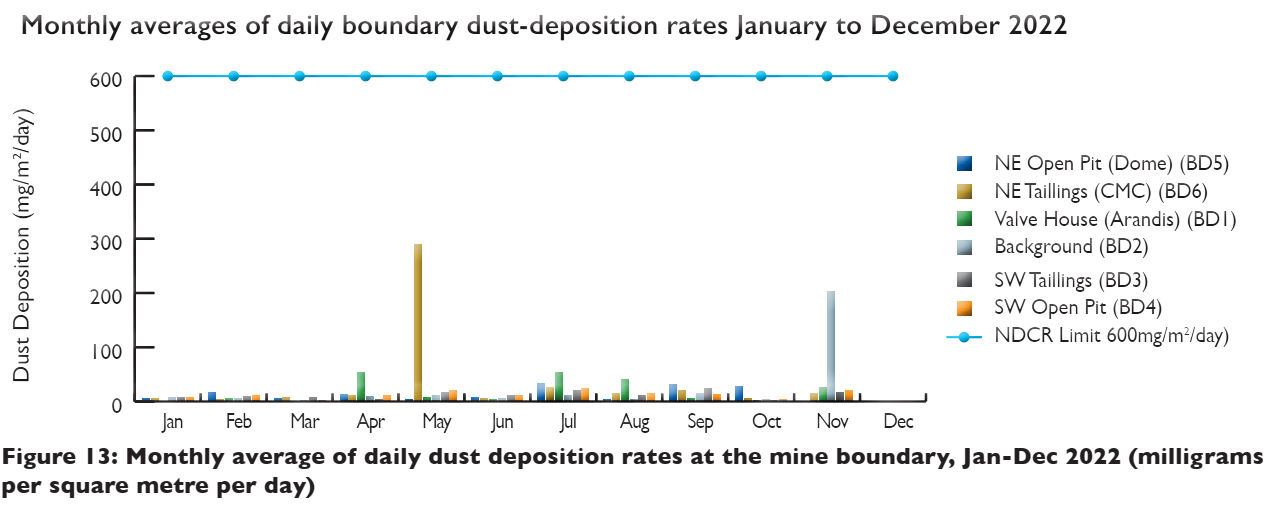

Fall-out dust is measured at six stations at different locations along the mine boundary (see the yellow dots on the map, Figure 11). The dust-fallout limit is 600mg/m2 per day with an annual average target of 300mg/m2 per day, as required by the adopted South African National Dust-Control Regulation (“SA NDCR”) standard.

During 2022, values measured at the six stations ranged between 0 and 291mg/m2 per day with an annual average of 18mg/m2 per day (see Figure 12).

All measured deposition rates were well below the selected or adopted SA NDCR standard.

Noise and vibration

In the absence of Namibian legislation on environmental noise and vibration, Rössing has adopted or referred to:

- the United States Bureau of Mines RI 8507 criteria for safe blasting, and

- the relevant South African National Standards Code of Practice, SANS 10103:2008 (SANS, 1992) for operational noise,

as internal reference limits.

Or

In the absence of Namibian legislation on environmental noise and vibration, Rössing has adopted/ referred as internal reference limits:

- the United States Bureau of Mines RI 8507 criteria for safe blasting, and

- the relevant South African National Standards Code of Practice, SANS 10103:2008 (SANS, 1992) for operational noise.

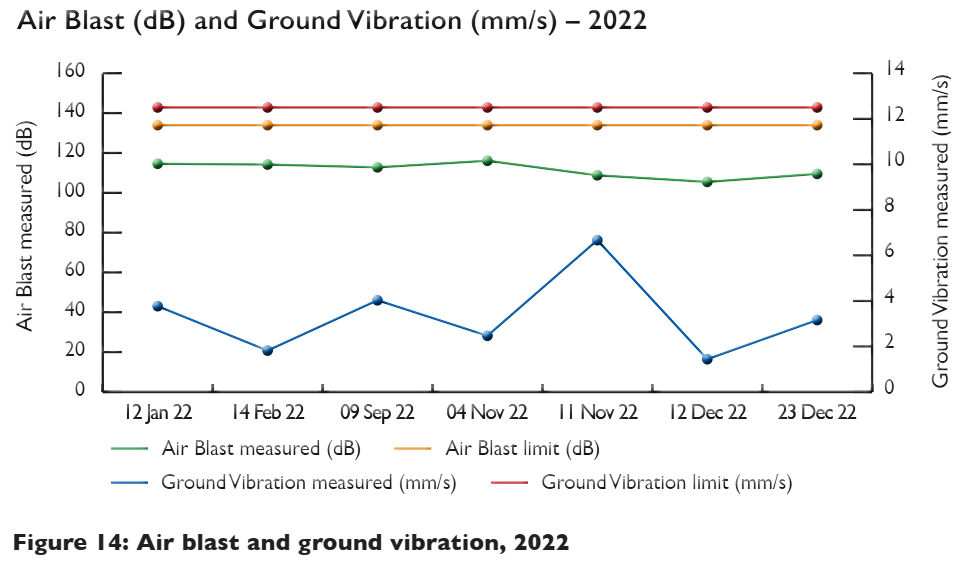

Noise and vibration are monitored at various points on and off site. Environmental noise is monitored according to a specific procedure and reported monthly to help identify events when these levels have been exceeded.

Noise & vibration monitoring – measures “air blast & ground vibrations” related to mining.

In 2022, both air-blast and ground vibration levels were consistently below the limits of 134 dB and 12.5 mm/s, respectively, see Figure 14. Blasting is only carried out in the open pit, and monitored at two places, on site and in Arandis.

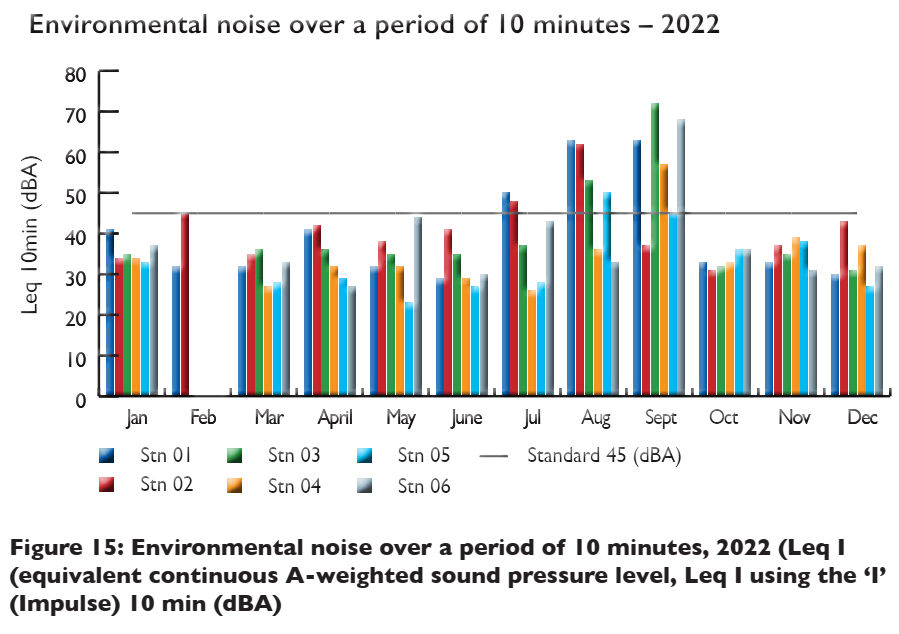

Environmental noise monitoring – measures natural background noise against noise generated by the operation.

Environmental noise is measured over snapshots of 10 minutes at six different sampling points or stations, namely Station 1 – Rössing Main Mine Access Road; Station 2 – Arandis Airport Gate; Station 3 – Khan River Valley; Station 4 – Khan River Rock Island; Station 5 – Khan Riverbed and Station 6 – Khan Riverbed. There were a few occasions during which environmental noise readings exceeded the Rössing internal noise level of 45 dBA (Figure 15). These exceedances were attributed to natural background windy conditions (bergwinds) experienced at the time of monitoring rather than to excessive noise generated during mining activities

Energy efficiency and greenhouse gas emissions

As part of the environmental commitment and priority given to protecting the environment, Rössing measures and manages its greenhouse gas (“GHG”) emissions and energy intensities. This assists in improving energy efficiencies and reduce GHG emissions. The sources of GHG emissions at Rössing include electricity and fuel consumption, the transporting of reagents and uranium oxide, blasting (use of explosives), waste management areas (the sewage plant, rubbish disposal and landfill site), and the extraction and processing of ore. The intensity of emissions is reported per unit of uranium oxide produced.

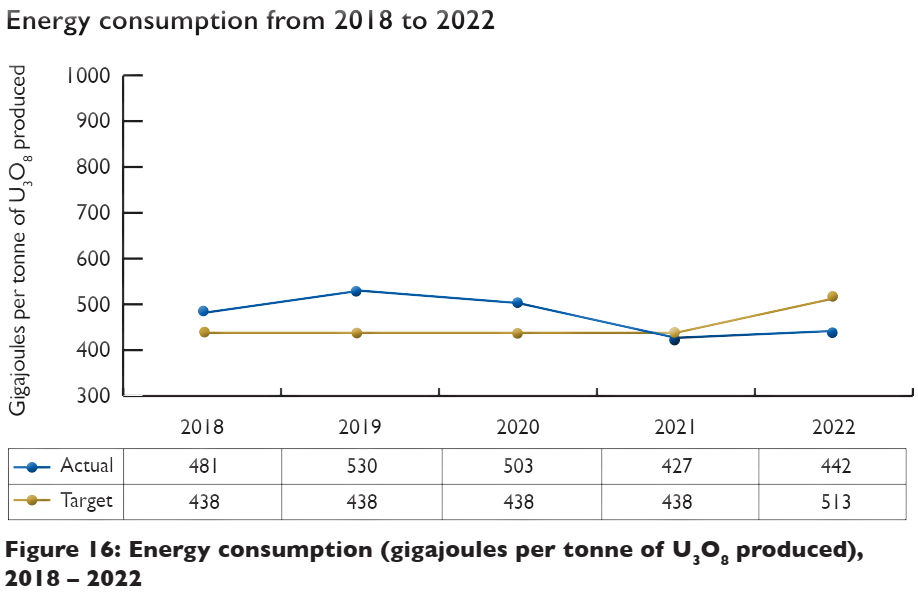

In 2022, the total energy consumption of the mine was 1,186,094GJ for 2,681 tonnes of uranium oxide drummed. This converts to an annual energy consumption of 442GJ per tonne (GJ/t) of uranium oxide produced, which is 14 per cent below the projected internal target of 513GJ/t uranium oxide produced (see Figure 16)

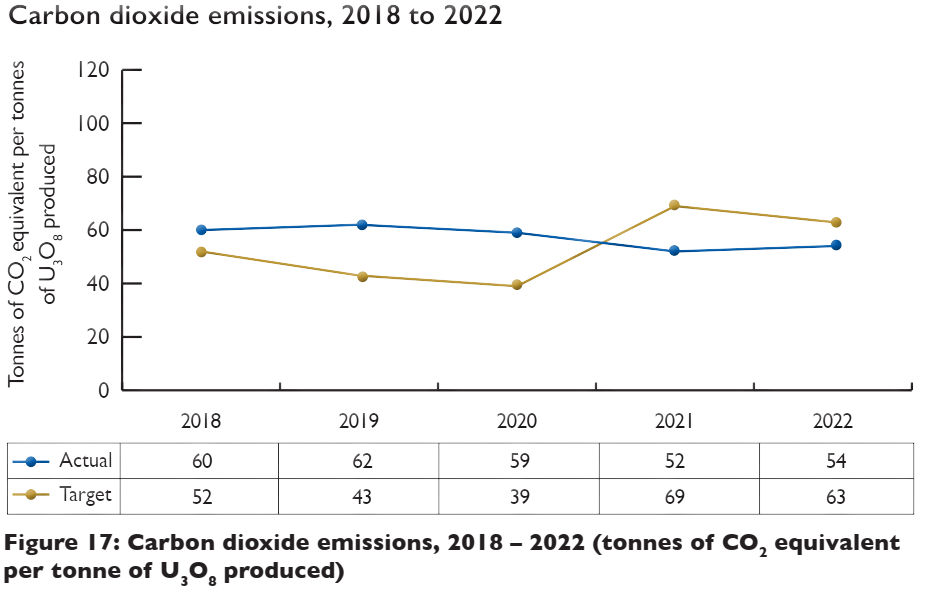

In the reporting year, emissions of carbon dioxide (CO2) per unit of production amounted to 54 tonnes of CO2 equivalent per tonne (CO2-e/t) of uranium oxide, which is below the internal of 63 tonnes CO2-e/t of uranium oxide for the year (see Figure 17)

Biodiversity management

The protection of environmental quality, including biodiversity, is important at Rössing. We take pride in the conservation of biodiversity within the ambit of the Rössing mining licence, in the surrounding communities, as well as in Namibia at large. Ecosystems and associated biodiversity at Rössing are managed through our Biodiversity Action Plan (“BAP”) that follows the mitigation hierarchy, which aims to prevent, minimise, rehabilitate, and restore Rössing’s footprint and impact on the ecosystem. Rössing continued to be involved in various biodiversity awareness campaigns and projects that aimed to create awareness and strengthen the understanding of biodiversity among the workforce, communities, and the Namibian population.

World Environmental Day commemorated on 4 June 2022 and learners with donated water cans

Environmental Day commemoration

In support of the Environmental Day celebrations on 4 June 2022, Rössing collaborated with Arandis Town Council, Rent A Drum and WesBank to commemorate the day under the theme “#OnlyOneEarth“. Donations of 20 trees and 10 water cans per school were donated to three schools in Arandis (Arandis Primary School, Kolin Foundation High and UB Dax Primary School). With these donations, Rössing aimed to encourage the youth to plant more trees in their local environments for the benefit of everyone.

Birdwatching day

In 2022, Rössing successfully hosted its 21st Annual Birdwatching Day. The event aims to give participants an experience to view the unique birdlife, and to promote a long-term interest in birds, linked to conserving local and wilderness biodiversity. For the past two years, the event was hosted virtually with immense success, however, in 2022 we reverted to visiting the mesmerising Walvis Bay Lagoon. Fifty three learners from nine schools participated in the event. With the aid of provisional birdwatching guides, participants could identify different bird species and get insight on associated facts (physical features and reasons for their evolutionary adaptations, diets, migration routes etc.).

Annual Bird watching event, 2022

Rössing’s commitment to Project Shine

As part of our social responsibility, Rössing continues to support the Project Shine clean-up campaign. Rössing was a founding member of the Project Shine initiative 15 years ago. With input from various stakeholders, the mine has sustained this project successfully over the years.

roject Shine, which is a clean-up campaign driven by the Swakopmund Municipality, aims to maintain the national road between Arandis and Swakopmund, with the focus having now been extended to include clean-ups along the coast as well. The project is also involved in educational and environmental awareness in the community, and more co-sponsors are being sought to contribute to the continuation of the project in the future.

Project Shine is also aimed at minimising the effects of waste on the environment and promoting environmental conservation – this objective has been successfully achieved for the past 11 years.

In 2022, Rössing donated N$100,000 to the continuation of the project; the funds were earmarked for supporting Project Shine to execute its mandate of cleaning up the roads and rolling out an awareness/ education campaign. Rössing also supports the project with an evaluator and a 4x4 vehicle on monthly evaluation sessions. By supporting such initiatives, Rössing aims to be the leader in environmental stewardship in Namibia.

Progressive rehabilitation

Progressive rehabilitation has been recognised as a key strategy for minimising mine closure liability or obligation and environmental risks. Mining activities disturb land through land clearance and infrastructures that support mining activities. The open pit, waste rock dumps, TSF, infrastructure, and the processing plant account for most of the footprint (land disturbed) at Rössing. Ninety per cent of the disturbed area at Rössing is in operational use; therefore, rehabilitation interventions are limited to demolishing redundant infrastructure and clean-up activities.

To leave all rehabilitation until mine closure is not best practise, therefore progressive rehabilitation is applied. Particular effort is made to land demolition and clean-up of redundant and decommissioned facilities and infrastructure. Since this happens throughout the life-of-mine, mining activities are not interrupted and continue as normal.

The proactive and progressive rehabilitation campaign which Rössing has embarked upon in 2022 was based on clean-up projects and rehabilitation work. Clean-up projects focus mostly on clearing land from waste which has accumulated at identified areas over the years without necessarily rehabilitating the land, and at this stage, the land remains within the operational footprint of the business. Rehabilitation, on the other hand, takes place outside operational areas.

The approach taken in 2022 was to proactively transport this waste to the final disposal areas and, in doing so, reduce the liability and associated cost at closure. Successful implementation of these projects requires thorough disposal strategies for future waste similarly generated through operations to avoid such waste from accumulating. Of the nine projects that were planned in 2022, five were successfully completed, one was deferred to 2023 and three are pending regulatory approval.

Upper Dome Gorge rehabilitation and slope stability

The Dome Gorge of Rössing Uranium is an ephemeral tributary of the Khan River, running along the eastern boundary of the Rössing’s mining licence and accessory works areas. During the early inception of the mine, river sand from this gorge was used for various purposes, which resulted in excavated holes and open edged trenches. In 2022, Rössing rehabilitated these pits by levelling the slopes and aligning them to merge background topography within the gorge.

Upper Dome Gorge: Rehabilitated legacy sand mine pit

Land-use management

Rössing is committed to limiting our impacts on land and biodiversity as much as possible. To achieve this, we use the “mitigation hierarchy”, which involves a combination of three factors:

- Avoidance: Wherever possible, prevent mining operations from encroaching onto undisturbed areas

- Mitigation: Where such areas have been disturbed, try to reduce the impact of the disturbance

- Rehabilitation: Following inevitable disturbance, rehabilitate the land

Guided by the above principles, particularly avoidance for 2022, Rössing’s footprint remains unchanged at 2,579.58ha since 2021. The open pit, waste rock dumps, tailings facility, infrastructure, and processing plant account for about 90 per cent of this disturbance.

Waste management

Mining operations are resource-intensive, consuming land, water, power, fuel, chemicals and construction materials to extract the metal held by the ore body. During the ore mining and metal refining processes, waste materials are produced, which consist of mineral wastes in the form of rock and process tailings, and other waste products generated by the services that support the mining process.

Mineral waste

During 2022, a total of 16.33 million tonnes of mineral waste were generated by the mine. This includes 8.97 million tonnes of tailings and 7.36 million tonnes of waste rock. By the end of December 2022, the total cumulative mineral waste stored onsite was 1,009.16 million tonnes of waste rock and 492.77 million tonnes of tailings.

Deposition of both tailings and waste rock generated in 2022 took place within our existing footprint and therefore our footprint remained the same for these facilities.

The footprints of the two mineral waste storage facilities have remained approximately the same since 2016. They cover an estimated area of 1,488ha northwest of the Khan River and are approximately the same size as the town of Swakopmund.

Non-mineral waste

Non-mineral waste is waste material that is not generated from the mineral ore, for example, redundant chemicals, conveyor belts, domestic waste, wood pallets, building rubble, scrap materials, used oils, and lubricants from maintenance activities. If waste is not stored and treated properly, it has a negative impact on the environment as well as the health and safety of the employees.

Therefore, the aim of managing waste at the mine is to promote the 3Rs to ensure that waste generated onsite is reused, recycled, recovered and disposed of in accordance with Rössing’s standards, applicable laws, regulations, best practices and permit conditions.

Waste on site is being managed by an integrated waste management contractor that was appointed in December 2019. The waste contractor handles both hazardous and non-hazardous waste streams and ensures proper treatment and disposal. As part of good corporate governance, Rössing monitors all recyclable waste streams (such as used oil, scrap metal, wooden pallets, and packaging materials) sent off site for treatment, recycling, or disposal by performing a verification assessment of contractors and facilities to confirm that the wastes are being managed correctly.

During 2022, a total of 4,636 tonnes of both hazardous (158 tonnes) and non-hazardous (4,478 tonnes) recyclable waste materials (mainly wooden pallets, scrap metal, paper and used oil) were taken off site for recycling purposes. Rössing continuously promoted the 3Rs (reduce, reuse, recycle) by supporting community projects through the donation of wooden pallets (267 tonnes) to vocational training centres (COSDEF, NIMT), Erongo Constituency Offices, Sonstraaltjie Kindergarten, Arandis Town Council, and the Urban Agricultural Project under the management of Swakopmund Municipality.

Recycling was also promoted through donations of 25 litre plastic containers (0.4 tonnes) to NIMT to be utilised at the campus nursery. There is a commendable increase in the amount of recycled scrap metal which left site in 2022 (4,079.7 tonnes) compared to 2021 (2,247.3 tonnes) due to ongoing progressive rehabilitation clean-up projects.

Among the hazardous recyclable waste, a total of 155 tonnes of used oil were taken off site for recycling in Windhoek. Used oil is stored in 210 litre drums and in bulk holding tanks which the oil recycler collects directly from site.

The rest of the recyclable and reusable waste is transported from the mine site to the Rent-A-Drum sorting facility in Swakopmund and further dispatched to the contractor’s refuse-derived fuel plant in Windhoek, while the non-recyclable waste, including domestic waste, is disposed of at the municipal landfill site in Swakopmund.

Contaminated solid waste includes both radioactive and non-radioactive contaminated waste materials (such as air filters, building rubble and processed mineral waste) that are generated from mining, workshops, as well as from processing plant areas. This waste stream is not permitted to leave the mine site under any circumstances.

In 2022, 2,388.7 tonnes of contaminated solid waste were disposed of on site, and 1,778 tonnes of both radioactive and mining-contaminated waste was disposed of at the tailings storage facility (“TSF”). The air filters (12.3 tonnes) and concrete rubble (571.0 tonnes) were also disposed of at the TSF while 27.2 tonnes of garden refuse generated was disposed of at the dormant landfill site. In an effort to improve the treatment of hydrocarbon contaminated soil, the integrated waste management contractor commissioned a trommel machine at the bioremediation facility. Efforts are underway to ensure that treated oil sludge meets the acceptable TPH clearance levels before it can be reused in the operational areas. In 2022, 456.4 tonnes of oil sludge soil were disposed at the bioremediation facility for treatment.

Safe and environmentally friendly reuse and/or disposal of used tyres remains a challenge for the business, due to a lack of recycling facilities in the country. A total 141.3 tonnes of tyres generated were collected and stored at the designated areas on site. The radioactive contaminated grease and diesel drums generated from Final Product Recovery (“FPR”) are also stored on site (at the Rodmill yard).

The different types of hazardous waste streams generated on site include PPE, filters, grease, redundant chemicals, batteries, used oil and other items, such as fluorescent tubes and e-waste.

We continuously ensure that our hazardous waste is managed correctly and disposed at a legally registered facility. A total of 666.9 tonnes of non-recylable waste was disposed off at the Swakopmund landfill site, while 21.19 tonnes of hazardous waste was disposed off at the Hazardous landfill site in Walvis Bay.

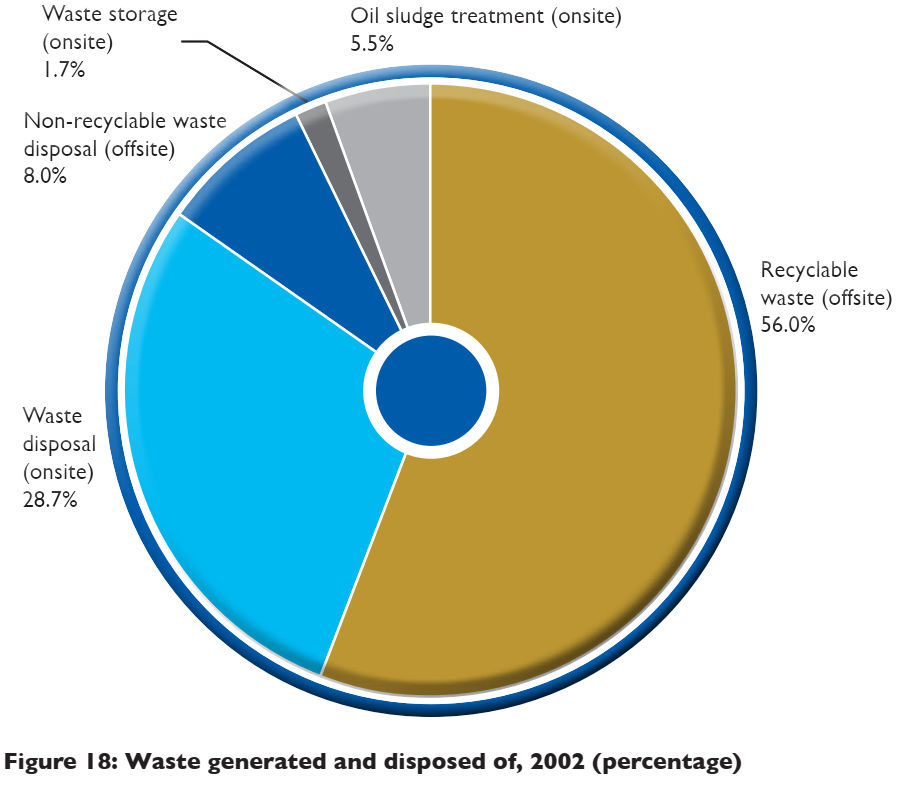

The medical waste stream is managed by the medical personnel on site and is transported to Medixx in Arandis before it is dispatched to Walvis Bay for incineration. A total of 0.03 tonnes of medical waste were generated, which is less than the 0.06 tonnes generated in 2021. Disposal certificates for all waste streams taken off site for recycling and disposal have been submitted by the recyclers and are accounted. All waste generated and disposed in 2022 is categorised and depicted in Figure 18.

Closure planning

The current Rössing mining plan foresees cessation of production at the end of 2026. The mine closure plan is in place and is reviewed and updated from time to time. The plan guides and consolidates the information on closure planning, and as such it functions as a tool to gather developing knowledge on a continuous basis. The closure planning and management addresses the major socio-economic considerations, both internally and externally. The proactive strategies are put in place and implemented in a progressive manner to limit future liabilities and prevent actual risk at closure.

Various infrastructure and features are classified as per the different domains and a plan exists for each domain. For example, in terms of the open-pit domain, the main feature is an open pit, which will not be backfilled and is envisaged to remain a mining void which will be reworked to prevent access for humans and wild animals.

Other prominent domains needing to be considered in terms of closure, are site infrastructure and the TSF, which also have dedicated closure intervention plans. The tailings will be managed in a manner that will prevent aeolian and fluvial soil erosion, while seepage will be recovered and allowed to evaporate in the open pit. The processing plant and the mine’s infrastructure will be demolished as per the demolition strategy and cost estimate. Materials not leaving the mine site will be disposed of safely in the open pit and sufficiently covered with waste rock so that they cannot cause future harm.

Closure planning has always been part of the business’s strategic planning over the years. However, with recent changes in majority shareholder and current life-of-mine approaching, extensive closure plan reviews were held to ensure practical and achievable targets/objectives. Rössing developed implementation plans for mitigation measures and calculated the associated closure costs, which were, to a high degree of certainty, confirmed to be sufficient.

The Rössing Environmental Rehabilitation Fund remains well in place, with annual contributions to the fund calculated according to the current total projected costs associated with the mine closure. The contributions are made to ensure sufficient funds are available at the time of closure.

At the end of December 2022, the fund had a cash balance of N$1,462 million and the net present value of the present closure obligation (referring to the full amount of close-down and restoration costs) to which Rössing is committed to at the balance sheet date of 31 December 2022 stands at N$1,799 million, including retrenchment costs. This is based on the life-of-mine ending in 2026; if this is extended, different figures will be calculated.